Crack Check Machine is a fully automatic machine designed for non-destructive testing (NDT) of ferrous iron and steel parts. It will discover cracks and other defects in parts which can be magnetised. It is suitable for both surface and subsurface cracks in components. This device is used to check cracks such as crankshafts, gears, camshafts, and components which are used by the Automobile industry.

There are many types of Cracks which can be Checked by machines, manufactured by MagnatechRmc. These include fatigue cracks, heat cracks, grinding checks, forging laps and shrinks etc. This machine is also known as Magnetic Particle Inspection Machines.

Crack Check Machine will discover such defects as fatigue cracks, heat cracks, grinding checks, forgings laps, shrinks and tears in castings, improper welds and inherent defects in metal such as seams and inclusions as well as cracks due to overstressing of parts. These defects may not be visible to the naked eye but can be discovered rapidly and accurately with Crack Check Machine Manufacturer made Machines.

MagnatechRmc is the leading manufacturer from Ghaziabad, dealing with Automobile, Aeronautical, and Railhead units.

We use the latest techniques and tools to deliver an unblemished range of products to our valuable clients. We offer these products in various models and sizes as per the details assigned by the customers.

We assure you that Crack Check Machine produced by us are of the best quality machine, having fine craftsmanship, superb reliability, long lasting and extremely rough and durable.

Special Features of the Magnatec Rmc Crack Check Machine

Speedily : It provides rapid and all over 100% inspection.

Productive : Provides highly replicable objective result evaluation. Also gives evidence and recording of tested results.

Eco friendly : There is no taint by coupling liquids.

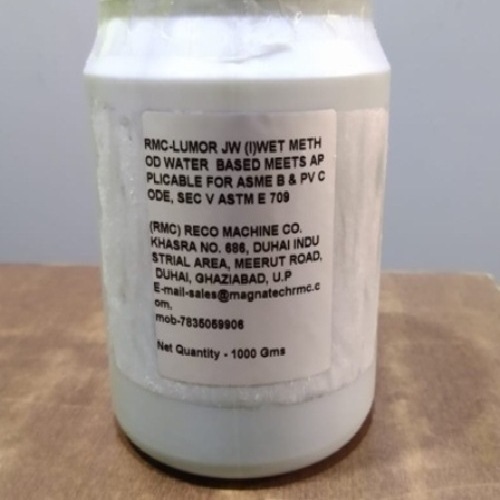

Easily Used at Surfaces : It can be used for both surfaces as dry type inspection and wet type inspection. Also detects both the surfaces and sub surfaces.

Residual Method : This Crack Check device allows you to examine cracks even after the sample has been removed.

Automatically Operated: It has a simple switch that operates as Current, Flux and combined.

Bed Coil : It has a special feature called bed coil for discovers circular cracks in it.

Easily Spotting: The Fluorescent powder quoting makes cracks visible under the UV light.

.jpg)